Manufacturing quality for construction equipment

People come to us when they need products with extreme toughness and durability. To ensure your demands are met, we set up control systems and comply with ISO standards.

Quality. In front.

What is quality?

The concept of quality vary depending on who you're asking. It can relate to the construction and assembly of an attachment, work tool, or component. It may also refer to the final visual and physical approval of a product. And some might refer it to the materials used in its production.

In collaboration with you, we establish the quality standards for your products, making sure that your product quality will be out in front of your competitors.

Want to learn more about how we ensure you the agreed-upon quality? Just keep on reading.

How we achieve

the Sjørring quality

- Comply with the high international industry standards

- Construct robust and durable products

- Use high-quality materials

- Adhere to precise and detailed working procedures tailored to your specifications

- Conduct continuous quality control

Assuring your requested quality

It's no joke that quality is one of our core values. It's our mantra that resonates from the very first meeting with you and all the way through our production facilities and extends beyond product delivery. Not only have we been ISO certified for years, we're proudly approved by premium brands in the industry.

The way we perceive the concept of quality encompasses the entire process and final outcome of an attachment product or welded component.

Every part of an attachment or component plays a crucial role in the final product. That's why we ensure that our skilled welders, technicians, and machinists bring their expertise to guarantee the highest possible quality for your product.

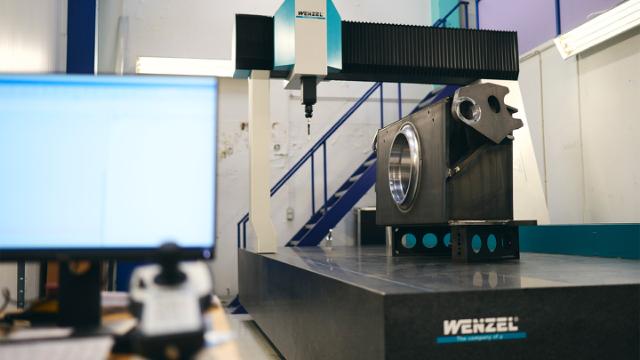

To ensure the expected quality, we have implemented a meticulous quality control system. Each product follows a detailed production guide tailored to specific customer requirements. This ensures that we adhere to all procedures and that we deliver the desired quality. Always.

We trust the quality that we deliver – and you are more than welcome to test it before engaging with us.

Certified quality

As part of the yellow goods industry, you've heard of the Hardox in My Body® certificate, right?

We've proudly held the Hardox in My Body® certification for years. The certificate is a quality seal by our main supplier of steel - the renowned SSAB - and the certificate highlights our commitment to quality.

However, this seal of approval is not the only thing signifying the quality that we aim to provide to you – our partner – time and time again. To improve our processes and quality, we are certified according to leading, global ISO standards:

These certifications further demonstrate our unwavering commitment to upholding the highest standards of quality and environmental management.

We comply with the strictest welding ISO certification available – the ISO 3834-2 – and the 18-point criteria outlined is our ultimate guideline to welding quality.

Hardox in my body – Sjørring to the core

Maximum strength and durability are key when manufacturing attachments and welded components for construction machinery.

That's why we use reinforced steel in most of our customer’s products. Depending on the type of product and its application, we carefully choose the right type and thickness of steel for your exact needs.

As mentioned previously, we're Hardox in My Body® certified. This certification guarantees that buckets bearing the Hardox logo are made of a minimum of 80% Hardox® steel. With our certification, we can assist you in obtaining the recognized logo on your own products.

When partnering with us, you benefit from our strong and long-lasting relationship with steel manufacturer SSAB and their onsite warehouse of steel. So, no shortage of materials around here. Not even when times are tough.

Joining forces

Whether a product is welded by a skilled hand or an automated robot, we maintain the same level of quality - the highest.

Every item that leaves our facilities undergoes rigorous quality checks because we believe in delivering your requested quality.

Our welding processes adhere to recognized tests and procedures (WPQR) and welding procedure specifications (WPS) that have been thoroughly tested and approved by FORCE Technology.

Would you like to work with us?

We are ready to assist you in any way we can, whether you have a question about our process or want to learn more about what we can offer.